Metal tube framing is revolutionizing the construction industry due to its ease of use, efficiency, and reliability. Compared to traditional wood or heavy steel framing, metal tubing provides a lightweight yet strong alternative that simplifies construction while maintaining structural integrity.

One of the biggest advantages of metal framing is its lightweight nature. Unlike wood, which can be bulky and inconsistent in size, or heavy steel, which requires specialized equipment to move, metal tubing is easy to handle and transport. This makes assembly faster and more efficient, reducing labor costs and installation time.

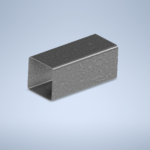

Precision is another key benefit. Metal tubes are manufactured with exact dimensions, ensuring consistency and eliminating the need for on-site modifications. This means fewer errors, less waste, and a smoother construction process. Additionally, metal tubing can be pre-drilled and pre-cut, allowing for seamless integration with other building materials.

Durability is also a major factor. Metal framing resists moisture, termites, and fire, unlike wood, which is prone to warping, rotting, and infestations. This reduces maintenance and increases the lifespan of a structure.

With its lightweight, precision engineering, and durability, metal tube framing is an easy and effective solution for modern construction projects.