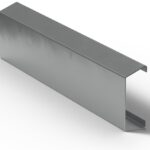

Galvanized C-channel is a popular structural component widely used in construction, industrial, and manufacturing applications due to its strength, durability, and corrosion resistance. Made from steel, the C-channel undergoes a galvanization process where it is coated with a layer of zinc. This protective coating acts as a shield against rust and environmental wear, making galvanized C-channel an ideal choice for projects exposed to harsh outdoor conditions, such as bridges, buildings, and outdoor frames.

The distinct “C” shape of the channel offers excellent structural support and load-bearing capacity while being lighter and easier to handle compared to other steel profiles. This makes it a preferred option for framing, structural reinforcements, and even conveyor systems. Its ability to resist rust ensures a longer service life, reducing maintenance and replacement costs over time.

C-channel comes in various sizes and thicknesses, allowing for customization depending on specific needs. Industries such as automotive, agriculture, and manufacturing rely on these channels for their reliability and cost-effectiveness. With its versatility, ease of installation, and resistance to wear and tear, Metal Framing is an essential material in modern construction and industrial design. Whether for new builds or repairs, it offers long-lasting performance in even the toughest environments.